A

Private, Family Owned Company

A

Private, Family Owned Company  A

Private, Family Owned Company

A

Private, Family Owned Company

Home

Company Heritage

Quality Hardwoods

Quality Softwoods

Treated Products

Managing Timberland

Locations

EMail

News

Quality Southern Hardwoods

ATI/Beirne: One of the Largest Hardwood Producers in the

World.

ATI/Beirne: One of the Largest Hardwood Producers in the

World.

Located in a prime, Southern hardwood region and equipped with

modern mill machinery, ATI’s Beirne facility is one of the

largest producers of quality hardwoods in the world.

Within reach of the fertile bottomlands of the Little Missouri,

Ouachita (“Wa-she-taw”) and Saline rivers – an

area with excellent drainage that regularly produces some of the

finest oak and ash in the country – ATI/Beirne turns out

over 40 million board feet of top quality hardwood lumber each

year.

Quality at Every Step

Each step of ATI/Beirne’s production process is aimed at

achieving the highest quality hardwood lumber from grade logs.

Since the highest grade

logs come from the surrounding river bottoms, which can only be

logged during late summer and fall, the mill regularly stores

over 10 million feet of hardwood logs on its concrete log yard.

ATI also operates satellite log storage facilities in Winnfield,

Louisiana, Hillester, Texas and Rockport, Arkansas. With this

huge storage capability, ATI/Beirne has a record of dependibility

for year-round production of quality hardwood products few can

match.

Since the highest grade

logs come from the surrounding river bottoms, which can only be

logged during late summer and fall, the mill regularly stores

over 10 million feet of hardwood logs on its concrete log yard.

ATI also operates satellite log storage facilities in Winnfield,

Louisiana, Hillester, Texas and Rockport, Arkansas. With this

huge storage capability, ATI/Beirne has a record of dependibility

for year-round production of quality hardwood products few can

match.

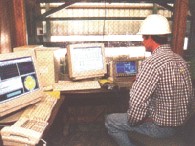

From the log yard, wood is brought into ATI/Beirne’s modern

mill complex. The sawmill consists of a computerized headrig and

a quad band which is fed by a newly installed, optimized and

computerized maxi-mill. This design positions each log to ensure

maximum utilization of fiber before feeding the center cant to a

computer-optimized thin-kerf gang saw. This permits exceptional

flexibility and high production volumes.

After separation by grade and species, the high quality oaks are

placed into a 1.75 million board foot pre-dryer. The wood is

protected and pre-dried to ensure consistent, bright, even drying

prior to being loaded into one of twelve modern dry kilns.

Recently, ATI/Fordyce, a satellite concentration and drying

facility, added a 500 thousand board foot pre-dryer and three

modern dry kilns to Beirne’s capacity.

A Wide

Varity of Hardwood Products

A Wide

Varity of Hardwood Products

In addition to producing kiln-dried, high quality oak and ash

lumber, utilized primarily in the moulding, cabinet and furniture

industries, ATI provides custom surfacing and a wide variety of

other hardwood products. ATI/Beirne regularly produces lumber for

oak flooring, frame stock, pallet material, gum and other

miscellaneous hardwoods, and has the capability of producing

large volumes of cross-ties and timbers of various sizes. While

much of the hardwood produced at Beirne is 4/4 lumber, a

substantial volume of 5/4 is also produced, and the mill can cut

special products on demand.

Faster and Better Service

Faster and Better Service

Because of ATI/Beirne’s flexibility and its large pre-dryer,

a customer’s special order can go from rough log to

kiln-dried and surfaced product in less than 45 days –

regardless of the time of year!

With such flexibility and high production volumes, ATI/Beirne has

become one of the world’s largest suppliers of quality

hardwood lumber.

Home EMail

Web Design By Butram System Engineering

Copyright 1999

Last modified 10/11/1999 20:15